The Dollfus & Muller felts are used on through feed sammying machines during hide processing in tanneries and are called sammying felts or Wringer felts. In a tannery, the sammying machines (Wringers) take out from the hides its surplus of water and its fats.

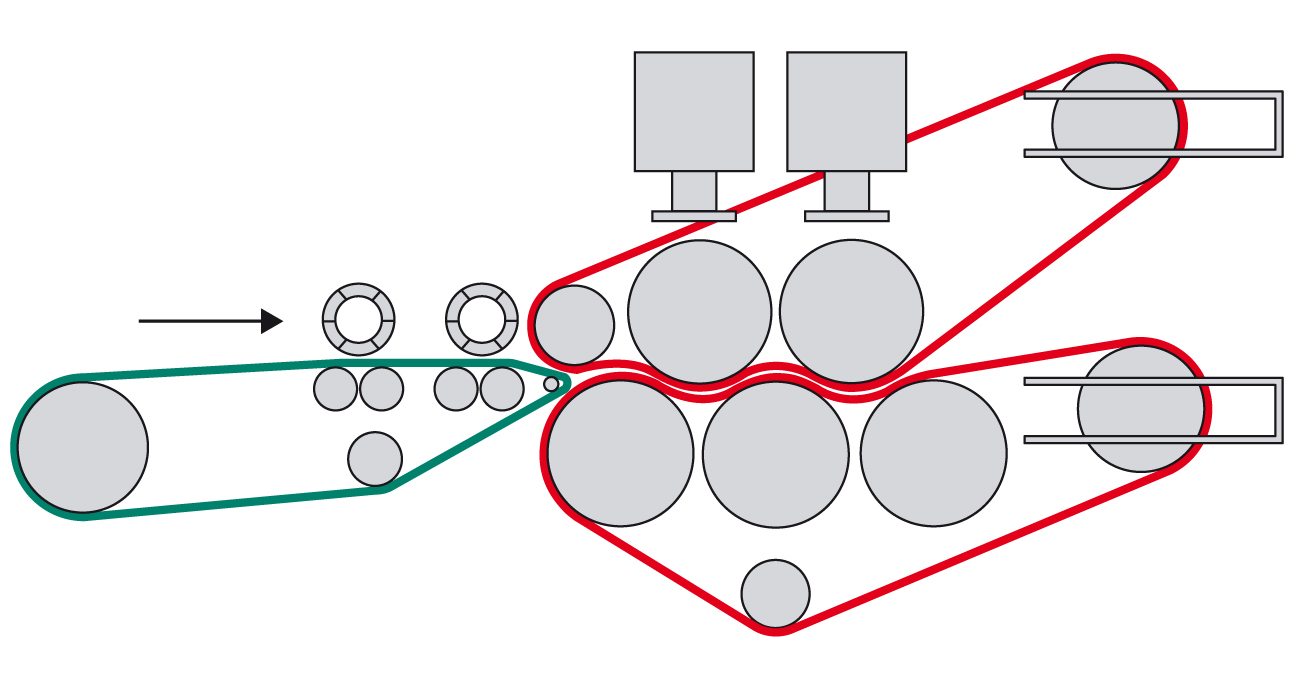

Dollfus & Muller sammying or wringer felts allow an immediate dewatering, degreasing and offer an excellent drainage. The hide runs between two felts (upper felt, lower felt) : strong pressure is applied by several cylinders. Dollfus & Muller felts are resistant to high pressure, easy to guide for a quick running start and allow an easy maintenance. The bottom sammying felts are also available in black color for a reliable infrared surface measuring, and are then called black bottom felts.

The Dollfus & Muller ESCO felts can be provided in various fibres mixes : either synthetic felts or mixed felts. Furthermore, different styles are available according to the sammying machine model. This wide range allows to provide one adequate solution for each leather processing :

- vegetal or chrome tanning (wet blue)

- crust, sides or full hides

- calf, lamb, goat, buffalo skins, etc…

Compatible machine brands

Felts for continuous spin-dryers (machines with 3, 5, 6, 7 or more cylinders)

Type of leather | Production | Type of machine | Process | Reference | Characteristics | |||

|---|---|---|---|---|---|---|---|---|

Composition | Weight (g/m²) | Thickness (mm) | Water permeability l/h/10cm² (under 2 bars of water pressure) | |||||

Cow, Buffalo, Calf, Pig, Goat, Sheep, Reptile | Automotive, upholstery | Machine with 5 or more cylinders | Wet blue, vegetal tanning, greasy hides | ESCO SX 95 / ESCO SX 95 black | 100% synthetic | 9500 | 18 | 350 |

Shoes, garments, bags | Machine with 3 cylinders | Wet blue, vegetal tanning, greasy hides | ESCO SX 85 / ESCO SX 85 black | 100% synthetic | 8500 | 17 | 300 | |

Wet blue tanning | ESCO M 85 / ESCO M 85 black | 30% wool 70% synthetic | 8500 | 17 | 300 | |||