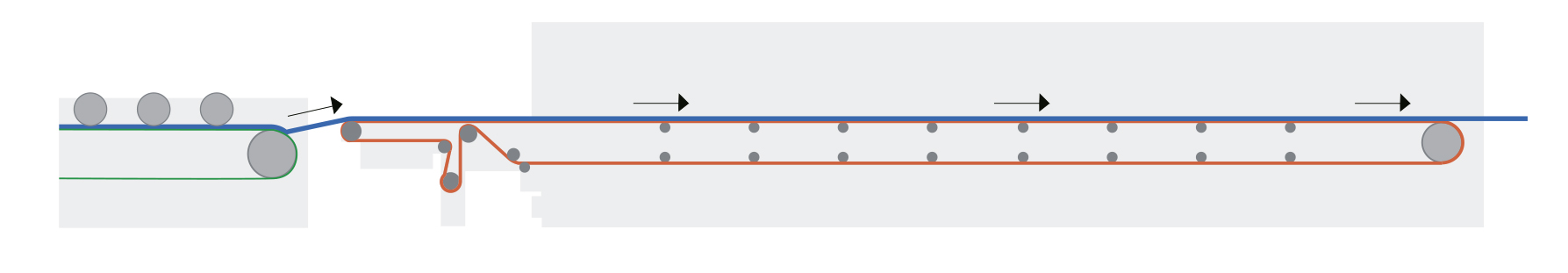

Dollfus & Muller is supplying conveyor belts for rotary, flat and inkjet printing dryers as well as felts for transfer printing.

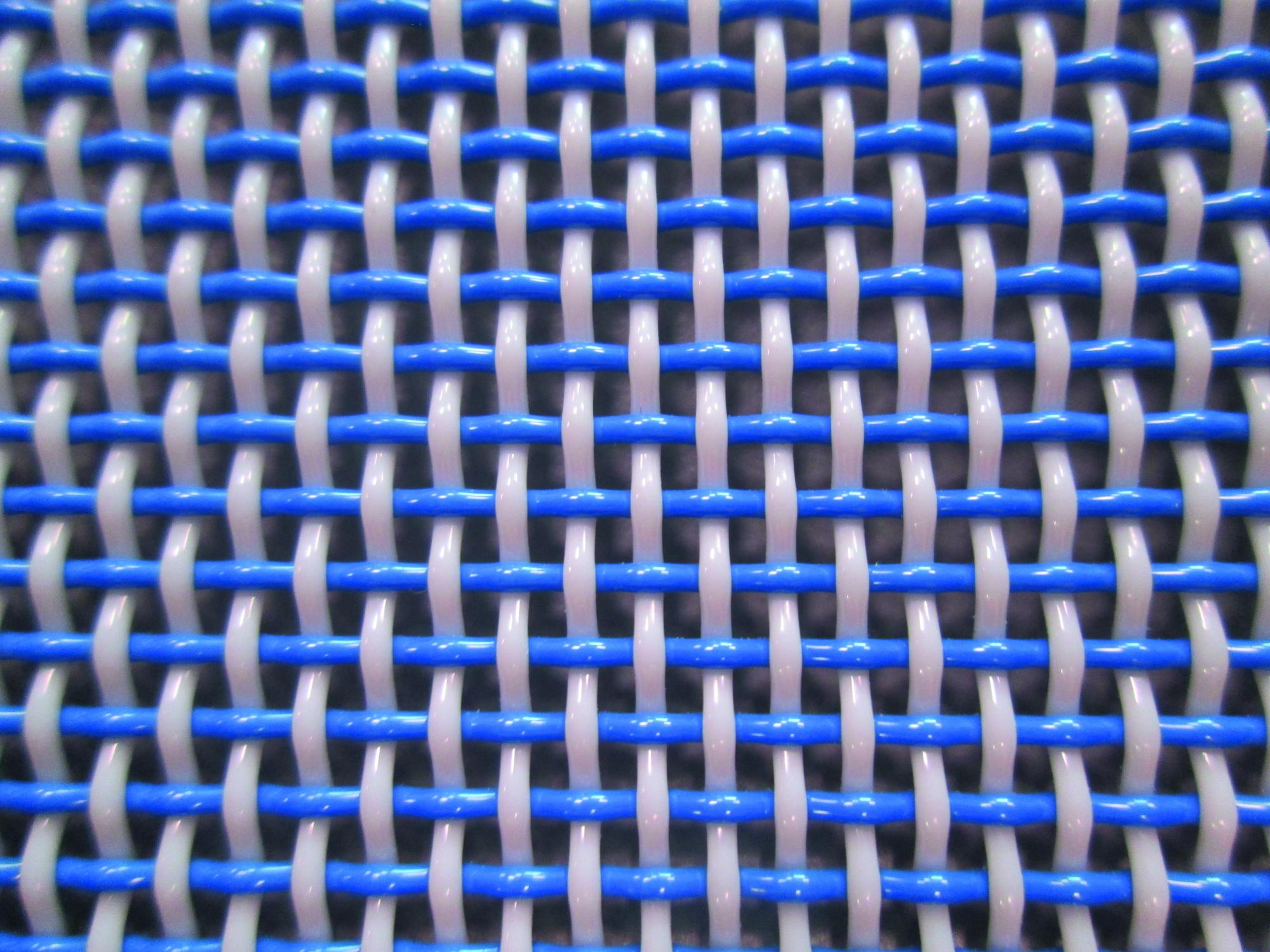

The Dollfus & Muller conveyor belts also called net, Aramid belts, conveyors or aprons, are used to carry the fabric through the printing dryers. The fabric, which has been printed, is fixed inside dryer with hot air.

The dryer belts need to be very resistant as the running conditions can be tough :

- Speeds range from 10 to more than 100 meters/min.

- Temperatures which may be as high as 230°C (450°F).

- Chemical resistance against the dyestuffs and the auxiliaries,

- as well as resistance against the abrasion created by the rolls inside the dryers and occasionally due to bad guiding.

Aramid belts, PTFE-coated fibreglass belts, PTFE belts, Kevlar® belts, polyester belts, Ryton belts, PEEK belts are available for textile printing dryers, Dollfus & Muller has worldwide, the widest range of dryer conveyors.

Dollfus & Muller open mesh conveyor belts allow an optimal drying and are of high dimensional stability specialy for the wider width. Specific dryer belt constructions have been developed to avoid any fabric marking (non marking dryer belts) for very sensitive fabrics such as flag printing or silk printing. As well, Dollfus & Muller has the strongest dryer belts available in order to be long lasting even with very old printing machines.

Compatible machine brands

Belt types | Max. working T° | Description |

| Recommended belts | Characteristics | |||

|---|---|---|---|---|---|---|---|---|

Insight | Reference | Composition | Air Flow: CFM under 124 Pa | Abrasion resistance | ||||

Rigid | 190°C / 370°F | Smooth and stable for high tension, 4x4 mm mesh | TAMIP KGT 40 | Kevlar® / fiberglass coated with Teflon® | 1710 | - | ||

260°C / 500°F | Standard smooth quality, 4x4 mm mesh | TAMIP GT 40 | Fiberglass coated with Teflon® | 1900 | - | |||

260°C / 500°F | Smooth quality 4x4 mm mesh reinforced by a Double Weft | TAMIP GT 40 DW | Fiberglass coated with Teflon® | 1700 | - | |||

260°C / 500°F | Standard smooth quality with reinforced construction 2x2 mm mesh | TAMIP GT 20 | Fiberglass coated with Teflon® | 1150 | - | |||

Flexible | 150°C / 300°F | Resistant quality | TAMIP C 928 | 100% Polyester | 1400 | ++ | ||

150°C / 300°F | Non-marking needle-punched fibres surface. | TAMIP CA 928 | 100% Polyester | 280 | - | |||

150°C / 300°F | Reinforced double layer belt for high width shrinkage fabrics. Used on some Stork print machines. | TAMIP C 498 | 100% Polyester | 1300 | ++ | |||

150°C / 300°F | Reinforced spiral mat with high dimensional stability | TAMIP Multiclip 80 | 100% Polyester | 1100 | ++ | |||

150°C / 300°F | Flat, strong and open conveyor belt developped for the carpet printing washing unit. | TAMIP C 4/4 | 100% Polyester | 1250 | ++ | |||

180°C / 350°F | Non-marking needle-punched fibers surface. Used on some Buser print machines. | TAMIP CA 928 R | PPS* / Aramid | 450 | - | |||

200°C / 390°F | Resistant quality for gas / thermo-oil heated dryers | TAMIP C 928 RR | PPS* / Aramid | 1500 | ++ | |||

230°C / 450°F | Resistant quality | TAMIP HT 500 N | 100% Aramid | 920 | +++ | |||

230°C / 450°F | Smooth surface for sensitive printed fabrics: silk, flags, etc. | TAMIP HT 541 N | 100% Aramid | 615 | +++ | |||

N.B.: Carpets with no abrasion resistance should never be used with a continuous washing system.

*PPS: Polyphenylsulfurate

- None + Medium ++ Strong +++ Very strong

Kevlar® and Teflon® are DuPont De Nemours registered trademarks