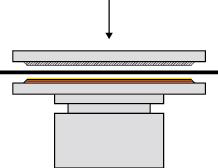

The skin is put on the felt pad. A hot graining or ironing plate comes down to press against the skin in order to give the final touch. The process can be repeated several times till the full skin is grained or ironed.

This machine is called Embossing machine, Hydraulic Press or Plating machine. Dollfus & Muller felt pads are delivered in 100% wool, with bevelled edges. The wool is washed and carbonised so that no piece of trash remains inside the wool. The standard thickness is 20 mm but other thicknesses are available. Concerning the density, in regards to the kind of leather processed and to the required embossing looked for, various density values are made (from 300 to 700).

Compatible machine brands

Production | Type of leather | Process | Reference | Characteristics | ||||

|---|---|---|---|---|---|---|---|---|

Composition | Weight (g/m²) | Thickness (mm) | Density | Finishing | ||||

Shoes, automotive, garments, upholstery, bags | Cow, pig, calf | Heavy embossing | PADO W 140 | 100% wool | 14000 | 20 | 700 | washed and carbonized wool |

Shoes, automotive, garments, upholstery, bags | Cow, pig, calf | Mid embossing | PADO W 100 | 100% wool | 11000 | 20 | 500 | washed and carbonized wool |

Shoes, automotive, garments, upholstery, bags | Cow, pig, calf | Soft embossing | PADO W 60 | 100% wool | 6000 | 20 | 300 | washed and carbonized wool |